our services

Product Category

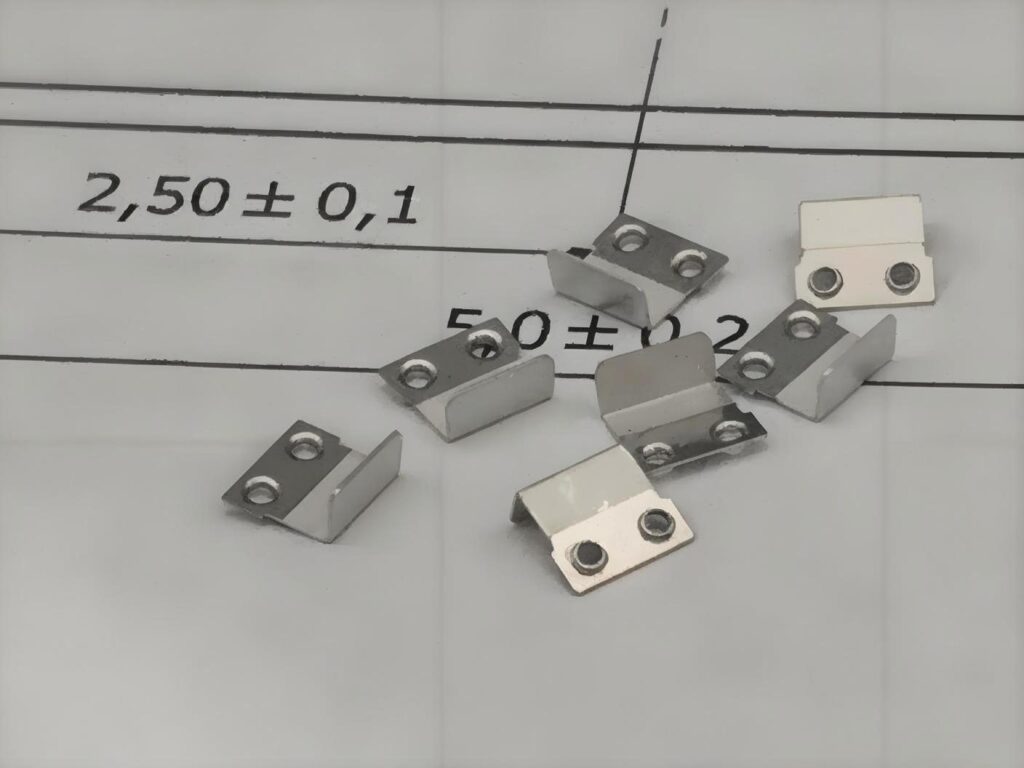

Metal Stamping

Stamping hardware refers to various operations such as stamping, stretching, bending, punching, etc. on metal sheets, which can quickly and accurately produce various metal parts. Applied in multiple fields such as electronics, automotive, medical devices, etc. Including terminals, connectors, fasteners, injection molded parts, etc

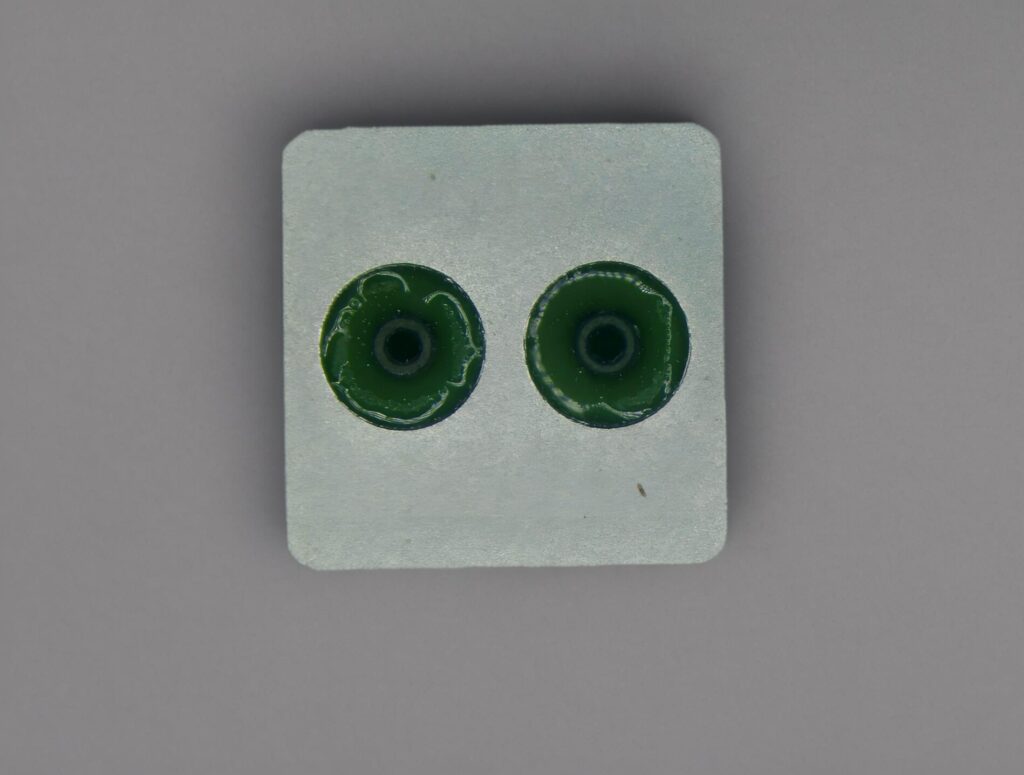

Insert Molding

Insert Molding is an advanced injection molding technique where pre-manufactured components (inserts) made of metal or other materials are placed into the mold before molten plastic is injected into the mold to form a complete product. The inserts can include nuts, bolts, electrodes, terminals, sensors, or even other plastic components. Through this process, the plastic securely encapsulates the insert, forming a single, integrated structure that enhances the part’s functionality, strength, and durability.Main application areas:Electronics & Electrical Industry、Automotive Industry、Medical Devices、Home Appliances,etc.

CNC precision parts:

CNC Precision Parts refer to high-accuracy components manufactured using Computer Numerical Control (CNC) machining. CNC machining is a process that utilizes pre-programmed computer software to control machine tools like lathes, mills, routers, and grinders. These machines can execute complex 3D cutting and shaping tasks with unparalleled precision and consistency, making CNC ideal for creating intricate parts to tight tolerances.Widely used in many fields: Aerospace、Automotive、Medical Industry、Electronics、Defense & Military

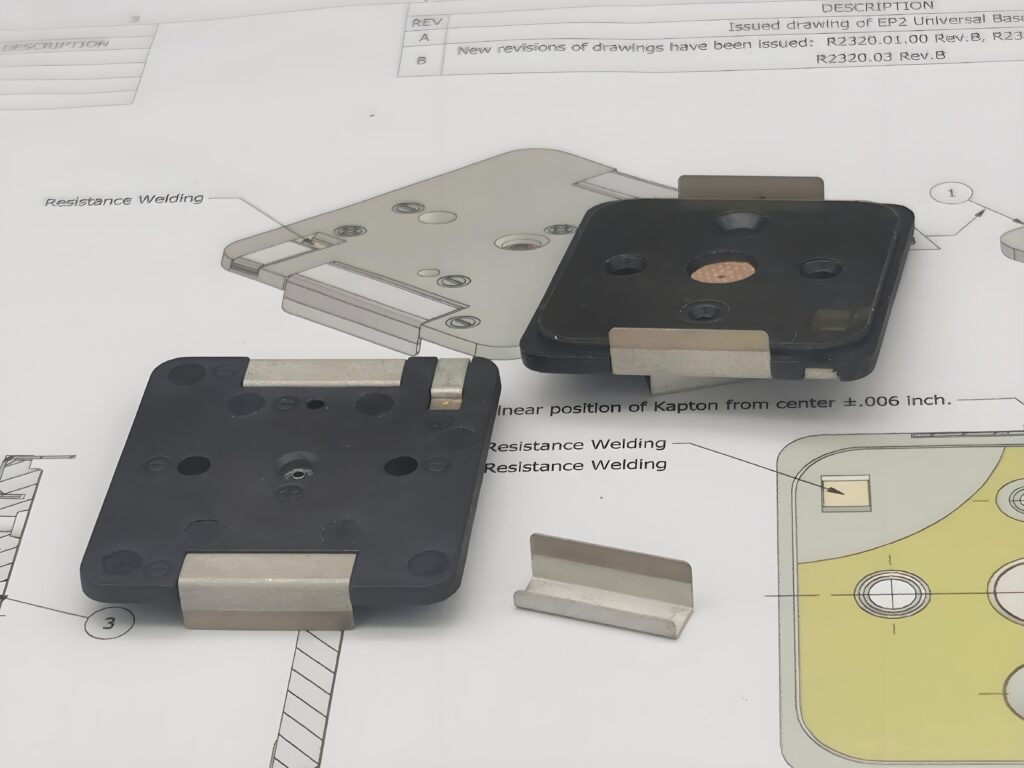

Metal and glass encapsulation

Metal and Glass Encapsulation refers to the process of hermetically sealing electronic components or other sensitive materials inside a protective enclosure made of metal and glass. This technique is primarily used to safeguard delicate components from environmental factors such as moisture, temperature extremes, and mechanical stress, ensuring long-term reliability and durability.