How to Solder a Terminal:

A Guide to Precision Soldering by Honglitai Precision

When it comes to precision components, soldering is an essential skill, especially for connecting solder terminals in various industries such as automotive, aerospace, electronics, and more. In this guide, we’ll walk you through the best practices for soldering a terminal, drawing on Honglitai Precision’s extensive experience in manufacturing high-quality precision parts and solder terminals for industries requiring exceptional reliability and durability.

Why Soldering Terminals is Critical

The success of soldering lies in the quality of the connection between the wire and terminal. A poor connection can lead to electrical failure or reduced performance, especially in high-stakes environments like automotive systems, avionics, or medical devices. With Honglitai Precision, we manufacture terminals with high precision, made from nickel-plated materials to ensure excellent conductivity and durability, even in harsh conditions.

Step-by-Step Guide to Soldering a Terminal

Step 1: Choose the Right Tools and Materials

Before starting, it’s important to have the right tools on hand. You’ll need:

- A high-quality soldering iron.

- Lead-tin solder or another compatible solder material.

- Nickel-plated terminals from Honglitai Precision for high durability.

- Heat shrink tubing (optional for insulation).

Step 3: Soldering the Terminal

- Tinning the wire: Strip about 5mm of insulation from the wire and apply a small amount of solder to the exposed copper. This step, known as tinning, ensures better conductivity and connection.

- Heat the terminal: Apply the soldering iron to the terminal for a few seconds before introducing the solder. This allows the terminal to reach the appropriate temperature.

- Apply solder: Once heated, touch the solder to the terminal and the wire simultaneously, allowing the solder to flow and create a secure bond.

- Cooling: After the solder has flowed evenly, remove the heat and let the terminal cool naturally.

Step 2: Preparing the Terminal

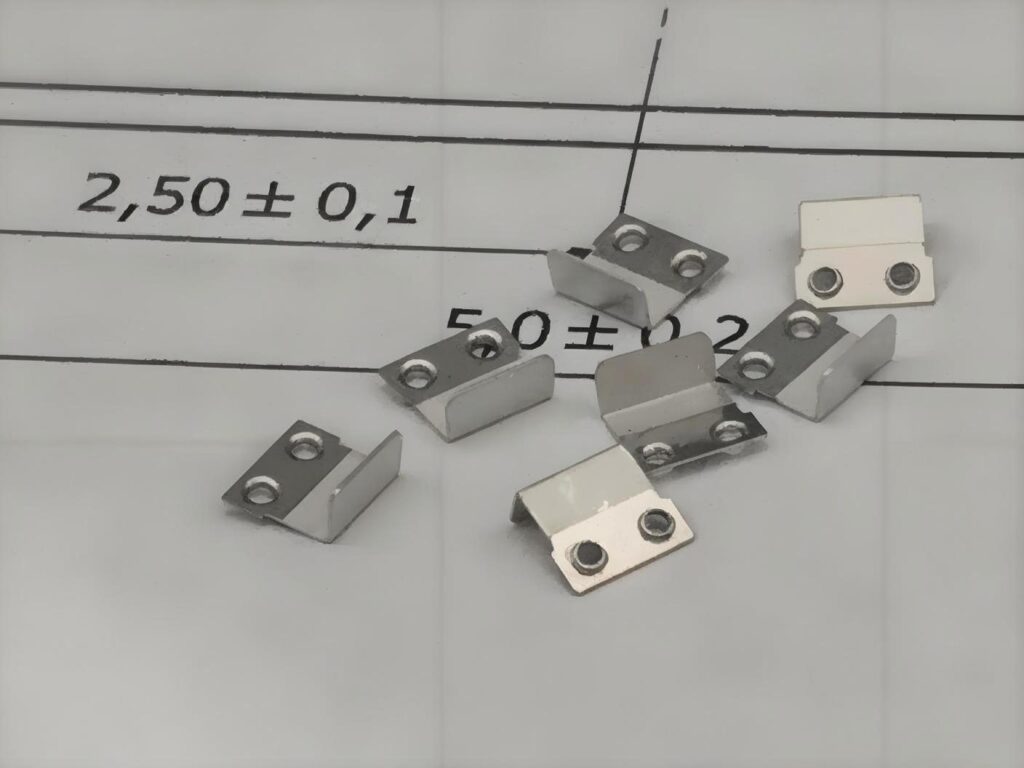

Our terminals at Honglitai Precision are engineered to meet high precision standards, ensuring smooth, burr-free surfaces that allow for perfect solder flow. Before you begin, make sure the terminal is clean and free from dust or debris. This step is critical for achieving a secure, high-performance connection.

Step 4: Inspect the Connection

Once complete, check the solder joint. It should appear shiny and smooth, with no gaps or uneven spots. A well-done solder connection ensures both electrical performance and long-term durability. Honglitai Precision’s terminals are designed with precision in mind, minimizing errors during this stage.

Common Issues and Troubleshooting

- Cold solder joints: If the solder joint appears dull, it may indicate a cold solder joint. Reheat the joint and allow the solder to flow smoothly.

- Excess solder: Avoid using too much solder, which can create short circuits. Keep the connection clean and precise, just like the components we manufacture at Honglitai Precision.

Why Choose Honglitai Precision for Your Solder Terminals?

At Honglitai Precision, we specialize in producing high-quality solder terminals that meet the exacting standards of industries such as electronics, automotive, and aerospace. Our terminals are made from nickel materials and feature tin-lead plating for enhanced performance. With over a decade of experience, we pride ourselves on providing our customers with reliable and durable products.

Our terminals are not only precise but also undergo rigorous surface treatment, including partial and full electroplating processes such as tin-lead and nickel plating, ensuring exceptional performance in both conductivity and corrosion resistance.Whether you’re in the electronics industry or aerospace, our solder terminals are the ideal solution for your needs.

Applications of Solder Terminals

Solder terminals are commonly used in:

- Aerospace: Reliable solder connections are essential for avionics and other critical systems.

- Automotive: From engine controls to infotainment systems, soldered terminals provide stable electrical connections.

- Electronics: In applications such as circuit boards, precise terminal connections ensure efficient energy transfer.

Frequently Asked Questions (FAQ)

Q: What type of solder is best for terminal connections?

A: Lead-tin solder is the industry standard for many applications due to its reliability and strength. At Honglitai Precision, we also offer terminals compatible with nickel and tin-lead coatings, ensuring a variety of soldering options.

Q: How can I ensure a reliable connection for critical systems?

A: Use high-quality terminals, like those manufactured by Honglitai Precision. Follow the correct soldering techniques and always inspect your connection for signs of weak joints or cold solder.

Q: Are your terminals suitable for harsh environments?

A: Yes. Our terminals are designed for both durability and high performance in extreme conditions, from aerospace applications to automotive systems.

Conclusion

Whether you’re working in aerospace, automotive, or electronics, soldering a terminal correctly is crucial to maintaining electrical integrity and ensuring the longevity of your product. With Honglitai Precision’s high-quality solder terminals, you can trust that you’re working with components designed for reliability, precision, and performance. If you’re ready to upgrade your production with the best solder terminals, contact us today to discuss your next order.